THE PROCESS

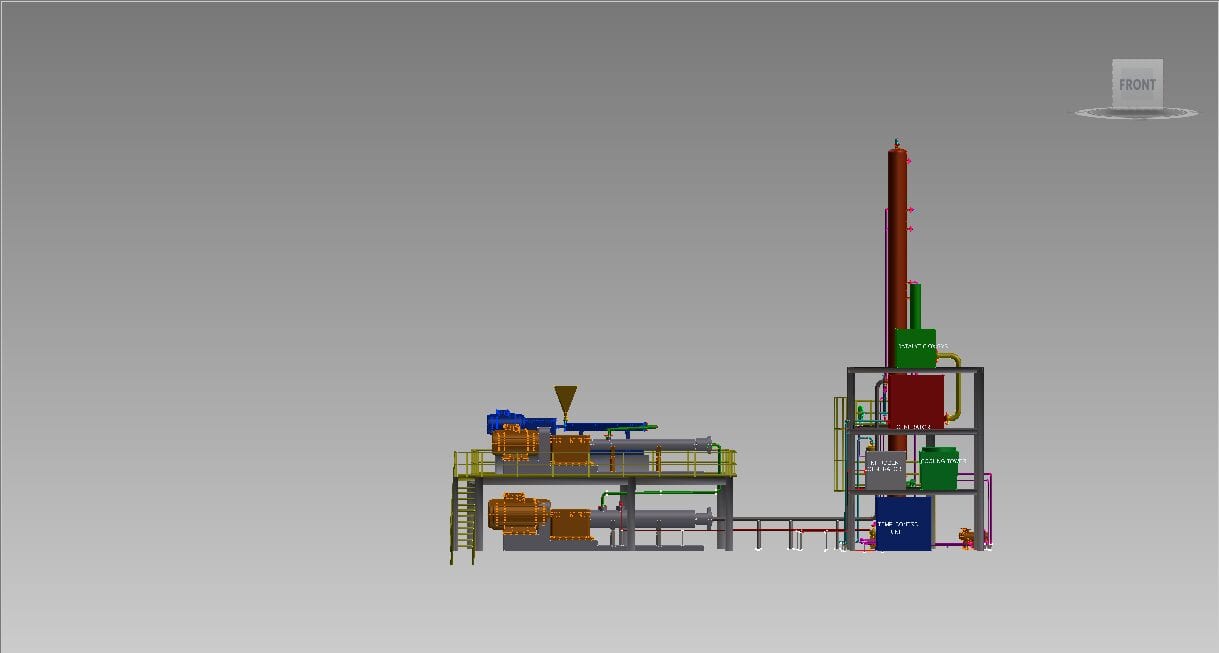

This Pyrolysis Process Description is intended to provide an overview of liquid fuel production.

Liquid fuel production is accomplished through the combined processes of Distillation and Pyrolysis. Raw plastic material is physically and chemically broken down through grinding and heating. It is then vaporized, condensed, and separated into three fuel products, (Naptha, Diesel, and bottoms) based on their individual chemical properties. Utility and auxiliary systems will be implemented in the process for the purpose of supplying power to primary and secondary equipment, supplying air to pneumatic equipment, and providing temperature and pressure control of process materials.

Waste plastic is supplied in the form of ¼” shredded chips of waste plastics. Prior to intake the plastic chips are cleaned, rendered free of any and all metal and inorganic fiber, and dried.

Waste plastic feed is continuously fed to Plastic Collection Hoppers where the raw material is aggregated and fed directly to Plastic Extruders. The Plastic Extruders are controlled by operators through control panel(s) and driven by Mechanical Drivers. The feed material is further mixed, mechanically broken down, pressurized, and heated in preparation for the next stage of the process.

PPIE Micro Refinery 01

PPIE Micro Refinery 02

Identification codes

Contact Us

USA

1100 East NASA Parkway, Suite 200 , Houston,

Texas-77058

CANADA

1300 King Street East

PO BOX 31016

Oshawa, Ontario, L1H 8N9

Phone

+1-281-914-4262